Mark Bidewell’s book recommendation:

2 Second Lean by Paul Akers

Paul Akers, one of the world’s top thought leaders, uses 2 Second Lean to simplify the Japanese principle of kaizen (continuous improvement). His approach makes everything more efficient by reducing waste.

“Prior to reading 2 Second Lean, I thought the lean concept sucked the fun and creativity out of business, but Paul and his team challenged my perception and turned this idea upside down”

It’s easy to go through life letting little things bug us. These small annoyances can be quickly fixed and instantly improve our home and work lives. For example, at the gym recently I had a major panic whilst on the treadmill – the clock on the wall said 7.45 am and I had a meeting at 8.00 am. Thankfully, it turned out the clock was nearly one hour fast! But the damage was done – the shock had taken the spring out of my step and caused unnecessary cognitive strain.

Lean – continuous improvement to make everything else easy!

After my workout I took the clock from the wall and changed it. ‘Cheers mate,’ said the guy on the treadmill next to me, ‘that’s been bugging me for weeks.’ This small improvement not only improved future workouts, but also had a positive impact on others.

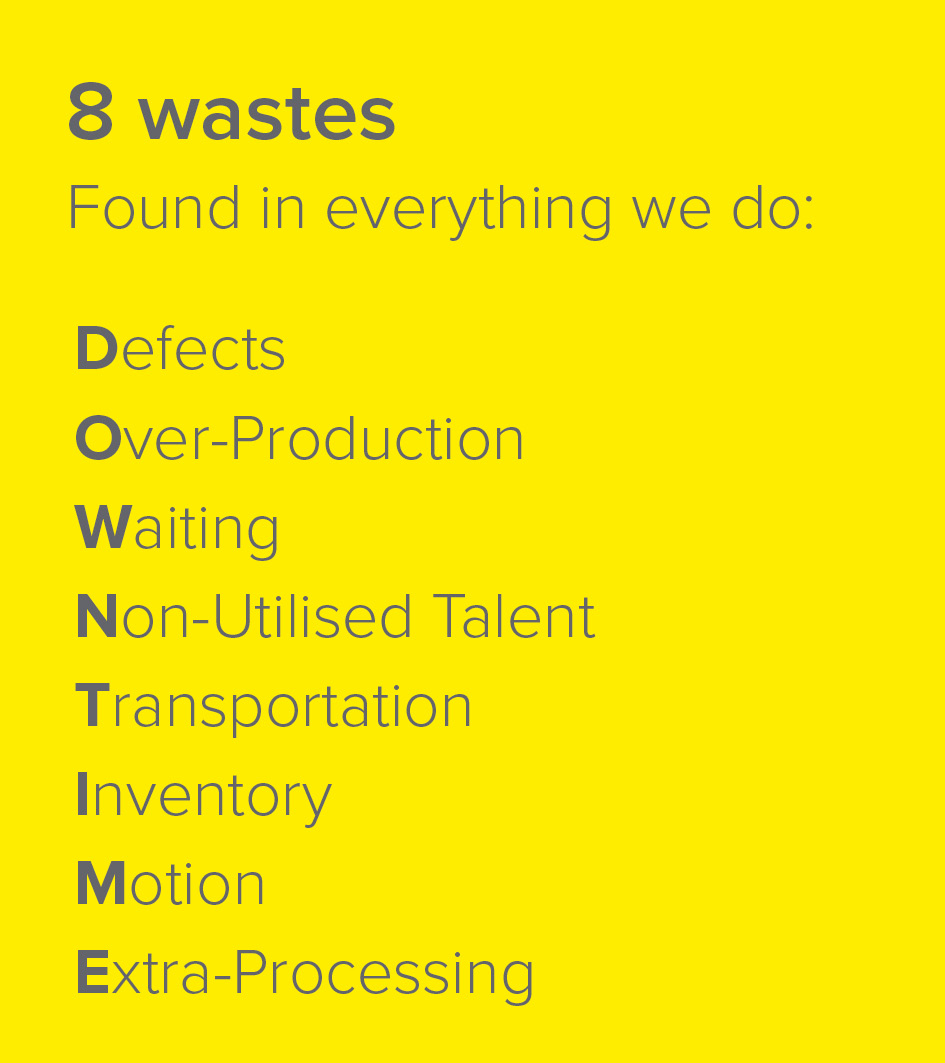

As Paul Akers says, ‘Finding the waste component is not a burden, it’s a game – a giant scavenger hunt.’ The magic behind the concept is that over time looking for two-second improvements becomes second nature and we continually find ways to remove waste.

Inspired and informed by the Toyota Production System (TPS), Paul’s lean business, FastCap, has grown from his garage to a multi-million dollar enterprise, he launches around twenty new innovative products a year and has been awarded Business of the Year multiple times. The company has built a culture of lean thinking with its highly effective daily morning meetings.

Lean has four key objectives for improvement

It is vital that any change is not at the mercy of another objective:

1. Safety

2. Quality

3. Simplicity

4. Speed

BISON lean in …

18 months ago, Team BISON began to embrace 2 Second Lean, reading a chapter a day together. Our number-one priority – to ensure that everything has a positive impact on our clients. The beauty of lean is it can be harnessed by all departments – for example our Client Success Advisers refine our systems to deliver to clients a faster, more helpful service, whilst our production department uses lean to enhance quality processes.

Lean is a culture and a community – we are especially keen to work with other people on this journey. If you are interested, or are already leaning in, we would love to talk!

Call 01622 677 541 or email mark@madebybison.co.uk

Click here to download a free PDF copy of the book

If you would like to keep updated with all news and developments, please subscribe to our mailing list.